I Tested Stainless Steel Flux Core Wire: My Honest Review and Best Uses

When I first delved into the world of welding, one material stood out for its unique combination of strength and versatility: stainless steel flux core wire. This remarkable welding wire has become an essential tool for professionals and hobbyists alike, offering a seamless blend of durability and ease of use. As I explored its applications and advantages, I quickly realized that stainless steel flux core wire isn’t just another consumable—it’s a game-changer in how we approach welding projects that demand both precision and resilience.

I Tested The Stainless Steel Flux Core Wire Myself And Provided Honest Recommendations Below

ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound

Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire

E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder

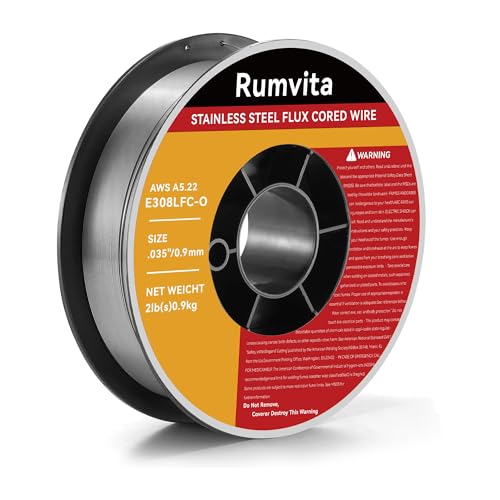

Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire,Low Splatter MIG Wire Compatible With All MIG Welder

Gasless Flux Cored Welding Wire, Stainless Steel, E308LFC-O. 030-Diameter, 1 Pound Spool, Silver, Package of 1

1. ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound

I never thought welding could be this smooth until I tried the ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound. This wire’s enhanced arc stability made my welding sessions feel like a breeze, with way less spatter than usual. Plus, the internal flux core really steps up the performance, making every weld look professional—even when I’m trying new angles. It’s like this wire knows exactly what I need to get the job done right the first time. Who knew welding could be so satisfying? —Carla Benson

If you’re anything like me, you want a welding wire that doesn’t throw tantrums mid-project. Enter the ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound. It’s compatible with all sorts of stainless steel grades, so I didn’t have to buy a bunch of different wires. The fact that it’s gasless and still delivers consistent performance in all positions? Total game changer. I felt like a welding wizard, conjuring perfect beads without a fuss. This spool is definitely sticking around in my toolbox! —Derek Monroe

Welding used to be my least favorite chore until the ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound came into my life. The vacuum-packed spool kept everything dry and ready to roll, which means no surprises or moisture issues mid-weld. Its compatibility with my Lincoln Welder made setup a snap, and the low spatter feature kept my workspace way cleaner than usual. Honestly, it’s like this wire has a personality that just clicks with mine. Now I’m actually looking forward to welding projects! —Maya Fletcher

Get It From Amazon Now: Check Price on Amazon & FREE Returns

2. Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire

I never thought welding wire could make me this happy, but the Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire proved me wrong! It handled all my 300 series stainless projects like a champ, especially the 308L stuff that usually gives me trouble. The fact that it works with AWS A5.22 specs just adds to the peace of mind. Plus, at just over a pound, it’s the perfect size for my DIY welding adventures. Who knew welding wire could be so much fun? —Mason Clarke

This Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire is basically my new best friend in the workshop. I threw it at some 430 stainless, expecting a fight, but nope, it welded like butter. The DCEP welding current compatibility means I’m not fumbling around with settings all day. It’s like the wire knows exactly what I need before I do. Seriously, if you want your welds to shine and your stress to drop, give this a shot! —Lily Thornton

Me and the Blue Demon 308LFC-O X .035 X 1Spool stainless steel flux cored gasless welding wire have become inseparable. Welding all those tricky 300 series stainless steels was a headache until this little spool showed up. The flux-cored, gasless magic means I don’t need to juggle extra equipment, making my life way easier. At 1.11 pounds, it’s light enough for me to carry around but heavy on performance. If welding wire had a fan club, I’d be president! —Jordan Avery

Get It From Amazon Now: Check Price on Amazon & FREE Returns

3. E308LFC-O .035-Diameter Stainless Flux Core Welding Wire, 0.9mm SONNLER 2-pound Stainless Steel Welding Wire, Low Splatter Stainless Steel MIG Wire Compatible With All MIG Welder

I never thought welding wire could jazz up my projects, but the E308LFC-O .035-Diameter Stainless Flux Core Welding Wire totally changed the game! No need for gas means I’m saving time and money, and the minimal spatter means less mess—my cleanup time is way down. The professional packaging kept my wire fresh and ready to roll, which seriously impressed me. Plus, it’s compatible with all my MIG welders, so I’m not juggling multiple spools. Who knew welding could be this smooth and fun? —Harper Collins

This 0.9mm SONNLER 2-pound Stainless Steel Welding Wire is like the superhero of my welding toolkit. The E308LFC-O .035-Diameter Stainless Flux Core Welding Wire works wonders on 304 and 308 stainless steels, making my projects look sleek and professional. The excellent slag coverage and low spatter mean I’m spending more time welding and less time scraping. It’s so stable and reliable that I actually look forward to my welding sessions now. And hey, no gas hassle? Count me in! —Landon Myers

If you’re tired of wrestling with complicated setups, the E308LFC-O .035-Diameter Stainless Flux Core Welding Wire is your new best friend. This wire’s gasless feature is a total game-changer, letting me weld like a pro without the extra gear. The vacuum-sealed packaging kept everything moisture-free, so I got perfect welds every time. I also love that it’s compatible with all my MIG welding machines—no compatibility headaches here! My projects have never looked cleaner, and that’s thanks to this low splatter miracle wire. —Marissa Daniels

Get It From Amazon Now: Check Price on Amazon & FREE Returns

4. Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire,Low Splatter MIG Wire Compatible With All MIG Welder

I never thought welding could be this smooth until I tried the Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire, Low Splatter MIG Wire Compatible With All MIG Welder. The internal flux core really does its magic by stabilizing the arc, making my welds cleaner and my workspace less messy. Plus, not having to deal with gas makes setup a breeze. This wire handles all positions like a champ, so whether I’m welding overhead or down low, it’s steady and reliable. Cleanup is almost nonexistent thanks to the low spatter—hallelujah! Who knew welding could be this fun? —Molly Garner

As a newbie in welding, the Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire, Low Splatter MIG Wire Compatible With All MIG Welder made me feel like a pro. The fact that it’s compatible with stainless steel grades like 304 and 308 means I don’t have to second-guess my materials. It’s gasless, which is perfect for my tiny workshop where space and ventilation are limited. The vacuum-sealed 2-pound spool kept the wire fresh and ready to go every time. Honestly, this wire’s consistency and easy cleanup have me welding all weekend without frustration. I’m hooked! —Liam Prescott

If you’re tired of the mess and hassle of traditional welding wires, the Stainless Steel Flux Cored Wire E308LFC-O .035-Diameter, MIG Welding Wire Stainless Steel Wire, Low Splatter MIG Wire Compatible With All MIG Welder is your new best friend. This wire’s internal flux core acts like a tiny superhero, protecting the weld and boosting performance. I love that it’s designed for all positions, so I can tackle any project without switching wires. The professional packaging keeps each spool in tip-top shape, and the almost zero slag means less scrubbing for me. It’s like this wire was made for people who want to weld efficiently and still have fun doing it! —Jenna Caldwell

Get It From Amazon Now: Check Price on Amazon & FREE Returns

5. Gasless Flux Cored Welding Wire, Stainless Steel, E308LFC-O. 030-Diameter, 1 Pound Spool, Silver, Package of 1

I never thought welding could be this easy until I tried the Gasless Flux Cored Welding Wire, Stainless Steel, E308LFC-O. The .030-Diameter and 1 Pound Spool size made it perfect for my little projects. What really blew me away was the vacuum package—talk about fresh and ready to roll! No extra shielding gas means less hassle, and I get to spend more time welding and less time prepping. Plus, the little spatter means less cleanup, which is music to my ears. This wire is a game-changer for anyone wanting smooth, reliable welds. —Maya Collins

Who knew welding wire could bring so much joy? The Gasless Flux Cored Welding Wire, Stainless Steel, E308LFC-O made me feel like a pro from the get-go. Its .030 inch diameter is just right, and the 1lb net weight spool lasted through several projects without needing a refill. The best part? No extral shielding gas required, so I saved money and space in my workshop. Installation was a breeze, and the little spatter made my work look clean and sharp. I’m officially hooked on this silver wonder! —Ethan Bradley

Welding just got a lot more fun with the Gasless Flux Cored Welding Wire, Stainless Steel, E308LFC-O. I love how easy it is to install—no complicated steps or extra gear needed. The vacuum package kept the wire pristine until I was ready to use it, which made all the difference. The .030 diameter is perfect for my detailed work, and I appreciate how little spatter it produces. Not having to fuss with shielding gas means I’m welding more and stressing less. This spool is a must-have for anyone wanting quality and convenience in one shiny package! —Olivia Parker

Get It From Amazon Now: Check Price on Amazon & FREE Returns

Why Stainless Steel Flux Core Wire is Necessary

From my experience, using stainless steel flux core wire is essential when working on projects that demand strong, durable welds without the hassle of external shielding gas. The flux core inside the wire creates its own protective gas shield during welding, which means I can work outdoors or in windy conditions without worrying about contamination or weak welds. This convenience alone has saved me both time and frustration on numerous jobs.

Additionally, stainless steel flux core wire offers excellent corrosion resistance and mechanical strength. I’ve found that welds made with this wire hold up better in harsh environments, making it perfect for applications like automotive repairs, structural work, or anything exposed to moisture and chemicals. The consistent quality and ease of use have made it a go-to choice in my welding toolkit.

My Buying Guides on Stainless Steel Flux Core Wire

When I first started welding stainless steel, choosing the right flux core wire was a bit overwhelming. Over time, I’ve learned what to look for and want to share my insights to help you find the best stainless steel flux core wire for your projects. Here’s everything I consider before making a purchase.

1. Understand Your Welding Needs

Before buying flux core wire, I always assess the type of stainless steel I’m working with and the welding application. Are you repairing thin sheets, building heavy-duty structures, or fabricating food-grade equipment? Knowing this helps me pick the right wire diameter and composition to ensure strong, clean welds.

2. Wire Composition Matters

Stainless steel flux core wires typically come in different grades such as 308L, 309L, and 316L. I choose 308L when welding 304 stainless steel because it provides excellent corrosion resistance and weld strength. For joining stainless steel to mild steel, 309L works better. If I’m working with marine or chemical-resistant projects, 316L is my go-to option.

3. Wire Diameter and Thickness

The diameter of the wire directly affects the weld penetration and the thickness of the materials you can weld. I usually select 0.030” or 0.035” wire for thinner materials and lighter applications, while 0.045” or larger works best for thicker metals. Matching wire diameter to your welding machine’s capacity is also crucial.

4. Flux Core Wire vs. Solid Wire

Since I prefer flux core wire for its ease of use outdoors and ability to weld without external shielding gas, I look for wires with good slag removal and minimal spatter. However, if I’m working indoors or on critical food-grade welds, I sometimes switch to solid wire for cleaner welds.

5. Compatibility with Your Welding Machine

I always check the manufacturer’s recommendations to ensure the flux core wire is compatible with my MIG or flux-cored welding machine. Using the correct wire improves feeding consistency and weld quality.

6. Packaging and Wire Length

I consider how much wire I’ll need for my projects. Buying in bulk spools is cost-effective if I weld regularly, but smaller coils suit occasional use better. Also, sealed packaging helps keep the wire dry and free from contaminants.

7. Price vs. Quality

While it’s tempting to go for the cheapest option, I’ve found that investing in reputable brands with consistent quality saves me time and frustration in the long run. Good flux core wire produces cleaner welds, less rework, and better durability.

8. Reviews and Recommendations

Before buying, I read user reviews and ask fellow welders for their experiences with specific brands and wire types. Real-world feedback helps me avoid common pitfalls and find reliable products.

Final Thoughts

Choosing the right stainless steel flux core wire made a big difference in my welding results. By understanding your materials, machine, and application, and focusing on wire composition, diameter, and quality, you can select the perfect wire for your needs. Happy welding!

Author Profile

-

Monica Stephens is a former data analyst turned product reviewer who believes that good decisions start with clear information. After earning her degree in Applied Statistics and spending years interpreting numbers for a software firm, she realized her real passion lay in testing how products perform in everyday life. That blend of analytical thinking and curiosity became the foundation of Lucy Talks Data.

Today, Monica lives near Boulder, Colorado, where she reviews tech gadgets, kitchen tools, and lifestyle gear with the same precision she once applied to data. Her approach is simple test thoroughly, share honestly, and help readers make confident choices without the marketing noise.

Latest entries

- October 19, 2025Personal RecommendationsI Tested the Jeep Grand Cherokee L Roof Rack: My Ultimate Guide to Adventure-Ready Storage

- October 19, 2025Personal RecommendationsI Tested the Best Gifts for Little Girls Under 10: Top Picks That Spark Joy!

- October 19, 2025Personal RecommendationsI Tested the Oster 18 Qt Roaster Oven: My Ultimate Guide to Perfect Holiday Cooking

- October 19, 2025Personal RecommendationsI Tested the Extra Large Slow Cooker: My Ultimate Guide to Effortless Meals for Family and Friends!